EOT Cranes Maintenance Service

5000 INR/Number

Product Details:

X

EOT Cranes Maintenance Service Price And Quantity

- 5000 INR/Number

- 1 Number

EOT Cranes Maintenance Service Trade Information

- Cash in Advance (CID)

- 10 Number Per Month

- 5-7 Days

- All India

Product Description

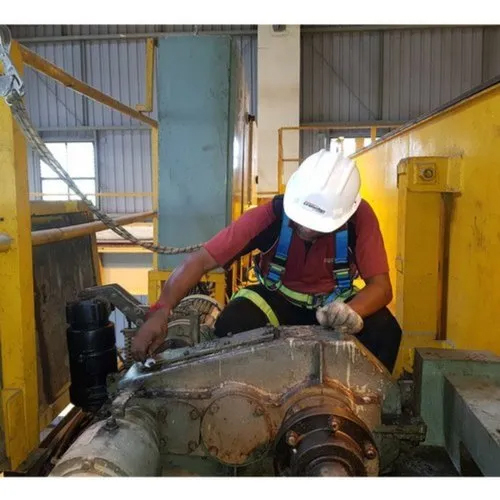

EOT Crane Maintenance Service ensures the optimal performance and longevity of Electric Overhead Traveling (EOT) cranes, critical for heavy-duty material handling. Crucial parts include the hoist, trolley, bridge, motors, and control systems, each essential for smooth operations. Regular maintenance involves inspections, lubrication, testing, and repairs. Technologies like diagnostic tools and advanced monitoring systems are used for precise assessments. Required tools include lifting equipment, torque wrenches, and alignment tools. Benefits include minimizing downtime, preventing breakdowns, and extending crane lifespan. Commonly used in industries like construction, manufacturing, steel, and automotive, EOT maintenance boosts productivity and safety. Completion times depend on crane condition but generally range from hours to days.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free